Marc Bouchet (Senior Investment Associate), TDK Ventures

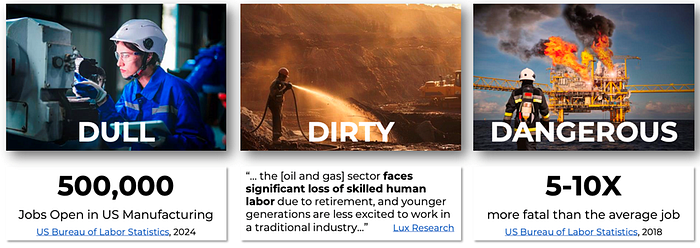

Heavy Industry is Hard on Humans

Heavy industry faces a trifecta of challenges that have persisted for decades: labor shortages, operational inefficiencies, and hazardous working conditions. These challenges stem from the inherently demanding nature of industrial environments, where jobs can quite readily be categorized as dull, dirty, and dangerous. From routine inspections in oil refineries to maintenance in chemical plants, these roles not only expose workers to significant risks but also contribute to mounting economic inefficiencies. Despite the undeniably negative connotation of all three classifications, the stakes (and costs) of these roles are consistently the highest. Equipment failures can halt entire operations, create safety hazards, and result in penalties for non-compliance with regulations. The global cost of unplanned downtime alone is staggering, with Fortune 500 industrials collectively experiencing 1.6 million hours of downtime annually, leading to financial losses estimated at $800 billion. Compounding this issue, industries are grappling with an aging workforce and a lack of younger talent willing to step into these physically demanding roles.

Inspection and maintenance are essential, but traditional, labor-intensive methods are increasingly unsustainable. Skilled technicians often face hazardous conditions — like remote pipeline sites or high-altitude inspections — while human error, fatigue, and physical limits compromise both reliability and safety.

This is where robotics steps in as a transformative solution. By automating inspection and maintenance processes, robotics can significantly reduce human exposure to hazardous conditions, improve operational reliability, and deliver substantial cost savings. Beyond addressing safety concerns, robotics offers the scalability and precision needed to meet the growing demand for operational efficiency in heavy industries. Automation can ensure consistent performance, reduce errors, and operate continuously without the need for breaks — qualities that are critical in environments where uptime is paramount. The potential market for robotic inspection solutions is vast, with projections estimating a need for over 500,000 robots and a market value of $116 billion by 2030 (Source: Baker Hughes, Global Energy Monitor, Energy Storage Exchange, Power Grid, S&P Global, OGI Research, Ibis World). Yet for decades, barriers such as high costs, limited technical capabilities, and complex integration requirements stifled widespread adoption. Robotics solutions were often seen as aspirational rather than practical, a luxury rather than a necessity.

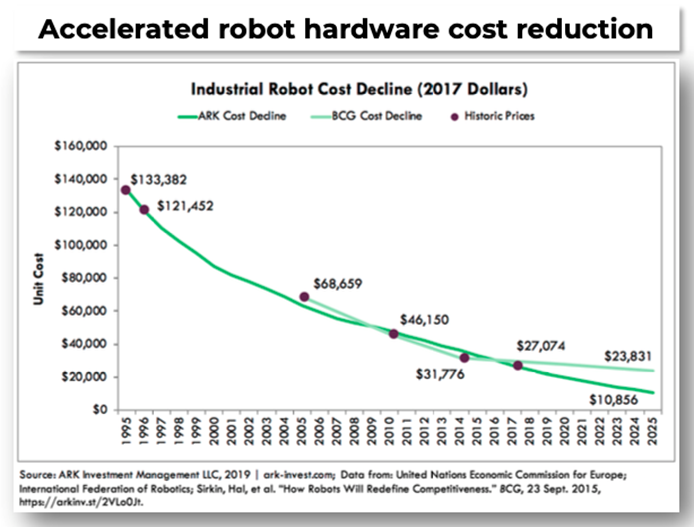

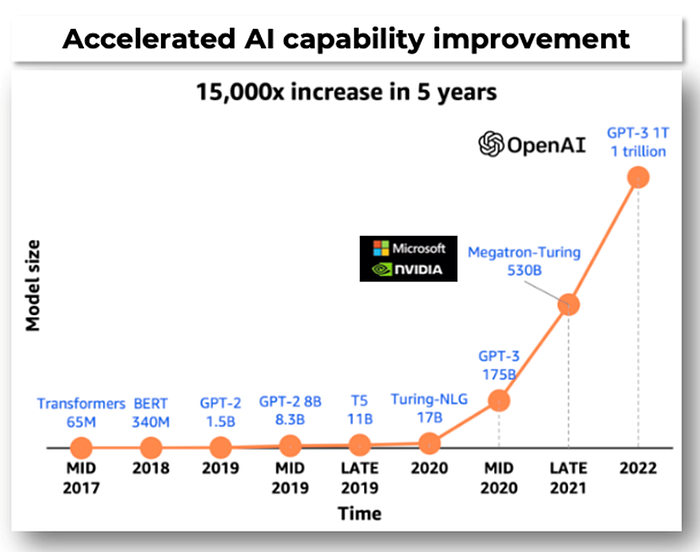

However, the tide has turned in recent years. Between 2017 and 2020, the robotics industry experienced a significant inflection point. Manufacturing costs for robots dropped below $30,000 per unit (Source: ARK Investment Management, 2019), while advances in artificial intelligence accelerated exponentially. OpenAI’s GPT-3, for instance, marked a 15,000x increase in AI model size, surpassing one trillion parameters. This convergence of affordability and capability has catalyzed a new era for robotics, enabling their deployment in industrial environments at scale.

Even with this inflection point marking an age of newfound viability for robotics, many startups continue to fail — for reasons we’ll explore below. Thankfully however, against this backdrop, ANYbotics has emerged as a leader — the “King of the Hill” in our parlance — demonstrating how cutting-edge robotic solutions can address the critical challenges of heavy industry.

The Evolving Landscape for Robotics Startups

The pathway to success for robotics startups is anything but straightforward. While the opportunities are immense, the landscape is fraught with challenges that require careful navigation. One of the most critical obstacles is the failure to define the “job to be done.” Many startups focus on technological innovation without clearly articulating how their solutions solve specific, high-value problems for their target customers. Successful startups begin by identifying a clear use case — such as automating routine inspections — and ensuring their solutions deliver measurable value from the outset.

A related challenge is demonstrating a clear return on investment (ROI). Industrial customers demand solutions that provide tangible benefits, such as cost savings or operational efficiencies, within a realistic timeframe. High-value automation opportunities — those where customers can recoup their investment within a year or less — are particularly attractive. However, many startups falter by failing to account for integration pain points. A robotic solution that requires costly and complex third-party integration can quickly erase its ROI potential. In short, as we started with — for robotics to be a realistic solution that customers will adopt en-masse, the use case and ROI must be clearly apparent (with all costs considered).

Another hurdle is navigating the complexities of scaling. While many companies successfully develop prototypes and secure pilot projects, the inability to scale production and accelerate sales cycles often leads to stagnation. Startups that can transition from pilots to scaled deployments within less than a year are far more likely to achieve long-term viability. This requires not only a robust product but also efficient manufacturing processes, streamlined distribution channels, and a clear go-to-market strategy. Lastly, robotics startups must contend with rapidly evolving technological standards. Hardware differentiation is no longer sufficient; customers increasingly expect integrated solutions that combine hardware with intelligent software. Startups must focus on generalizable autonomy and leverage data collected by robots to train proprietary AI models, ensuring long-term defensibility and scalability. This necessitates a multidisciplinary approach, bringing together expertise in mechanical engineering, computer vision, and AI development. Then, startups have to– navigate the complexities of scaling. Many companies develop prototypes or pilot projects, but cannot scale production or accelerate sales cycles, leading to stagnation. A startup must demonstrate the ability to scale within a year to achieve long-term viability. This requires a robust product, as well as efficient manufacturing processes, streamlined distribution channels, and a clear go-to-market strategy.

The most successful robotics companies will be those that combine robust hardware and intelligent software to deliver solutions that are both out-of-the-box and adaptable to a range of industrial needs. By addressing specific pain points, demonstrating clear ROI, and scaling efficiently, these startups have the potential to revolutionize industries.

ANYbotics: Pioneering Industrial Inspection Robotics

ANYbotics, a startup based in Zurich, Switzerland, epitomizes the qualities needed to succeed in this challenging landscape. Founded in 2016, the company is transforming industrial inspection through its innovative approach to robotics. By integrating state-of-the-art hardware, advanced AI, and intuitive software, ANYbotics delivers solutions that not only address immediate industrial challenges but also provide reliable and rapid ROI for customers. Their flexible business model includes equipment sales, leasing (“Robot-as-a-Service” or RaaS), and subscription-based software offerings (“Software-as-a-Service” or SaaS).

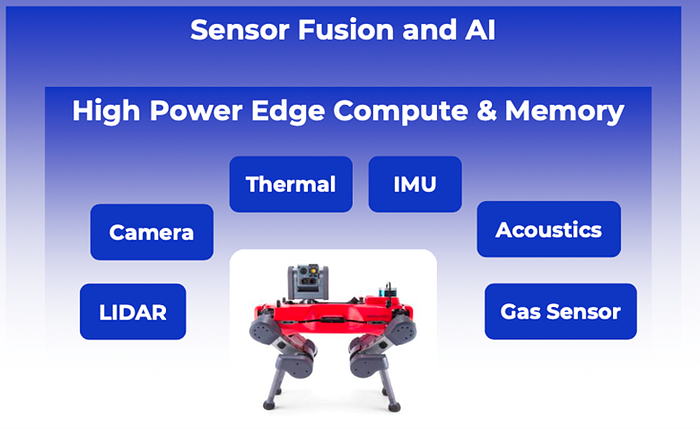

At the heart of ANYbotics’ success is its flagship product, the ANYmal-D quadruped robot. Designed as an automated inspection solution for heavy industry, the ANYmal-D stands out for its unique combination of technological capabilities:

- Customer-driven inspection intelligence: The ANYmal-D integrates seamlessly into industrial IoT environments, offering advanced inspection capabilities that create a digital twin of the operating environment. With edge computing, computer vision, and API connections to platforms like SAP, Oracle, and AWS, the robot ensures comprehensive data integration and actionable insights.

- Practical industrial autonomy and mapping: Equipped with multi-sensor fusion technology (3D SLAM), the ANYmal-D combines cameras, LIDAR, and IMU sensors to operate effectively in GPS-denied environments and track operations across multiple floors. This capability is crucial for navigating complex industrial settings.

- Industry-leading motion control: ANYbotics leverages deep neural network reinforcement learning to optimize the robot’s motion control for rugged environments. This technology enables the robot to handle uneven terrain, stairs, and other physical challenges with ease.

- Industrial-grade reliable hardware: The ANYmal-D is built from the ground up with industrial applications in mind. With 99% mission success rates and certification to IP67 and ATEX Zone 1 standards, the robot is both durable and dependable. Its user-friendly interface includes fleet management capabilities for streamlined operations.

ANYbotics has successfully avoided the pitfalls that plague many robotics startups. By focusing on specific industrial use cases, such as autonomous routine inspections, gas leakage detection, and 3D model updates, they have demonstrated strong customer traction. Clear ROI metrics show hundreds of thousands in annual savings and sub-one-year payback periods for many customers. Furthermore, their RaaS model caters to the needs of “digitally native” customers, ensuring scalability and adaptability as market demands evolve.

ANYbotics: King of the Hill

ANYbotics has firmly established itself as the “King of the Hill” in industrial robotics, distinguishing itself across four key dimensions. Its technical advantage is unparalleled. By combining robust hardware with a comprehensive software suite, ANYbotics enables fully autonomous inspection missions that set a new benchmark in the industry. Among quadruped robots, the ANYmal-D stands out for its tailored design, ease of deployment, and superior performance in heavy industry use cases. Its form factor outshines alternatives like tracked robots, drones, and humanoids, offering unmatched versatility.

What truly sets ANYbotics apart is its commitment to being customer-driven and “out-of-the-box” ready to deploy. The company’s focus on building solutions that solve specific customer problems without requiring extensive customization or integration efforts has been a game-changer. By taking a holistic view of customer needs, ANYbotics has designed a platform that integrates seamlessly into existing workflows while delivering measurable value from day one. This customer-centric approach has not only allowed them to gain significant market traction but has also positioned them as a trusted partner in the industrial sector.

Third, ANYbotics’ track record of execution speaks volumes. With over 100 robots sold to high-consequence early adopters, the company has demonstrated consistent year-over-year growth. A well-established supply chain and strategic manufacturing partnerships have enabled them to reduce costs while scaling production. Finally, the expertise of their leadership and technical teams is a critical asset. Led by top executives and researchers from ETH Zurich, ANYbotics boasts over 75 years of combined experience in scaling high-growth tech companies. This experience has been instrumental in driving innovation and ensuring operational excellence.

The impact of being the “King of the Hill” extends far beyond market dominance. ANYbotics has set a new standard for industrial robotics, demonstrating that customer-driven innovation and a focus on practical, deployable solutions can unlock tremendous value. By aligning their technological advancements with the broader needs of the industry, they have not only captured market share but have also laid the groundwork for future growth and expansion into adjacent sectors.

Strategic Synergies with TDK Ventures

TDK Ventures’ decision to partner with ANYbotics stems from a shared vision for the future of industrial automation. Through extensive due diligence, we evaluated the ANYmal-D’s capabilities firsthand, pushing its technology to failure points and exploring its potential in real-world scenarios. The results were nothing short of impressive. ANYbotics has not only developed a robot that excels in some of the industry’s most challenging environments but has also embodied a customer-first ethos that aligns perfectly with TDK’s values.

The synergies between ANYbotics and TDK Ventures are extensive. TDK’s business units offer several potential opportunities for collaboration in areas such as advanced sensing (e.g., MEMS gas leak detection), edge AI (e.g., TDK SensEI), and power electronics. As robot deployments scale, these collaborations will play a critical role in optimizing performance and expanding capabilities. Beyond heavy industry, ANYbotics’ technological platform has the potential to address challenges in other sectors, including infrastructure, utilities, agriculture, and logistics. By applying their expertise to new use cases, ANYbotics can unlock additional value and drive innovation across a broader range of industries.

Looking to the future, ANYbotics’ potential extends far beyond heavy industry. Their development ethos, centered on robust hardware and scalable software, positions them to address a wide range of sectors, from energy and utilities to infrastructure and beyond. The ability to adapt their platform to meet the unique needs of various industries ensures their relevance and impact for years to come.

Why We Invested in ANYbotics

At TDK Ventures, our investment in ANYbotics reflects a belief in their ability to redefine industrial inspection. The challenges facing heavy industry — from labor shortages to operational inefficiencies and safety concerns — demand innovative solutions. ANYbotics has risen to this challenge, delivering groundbreaking technology that addresses these pain points while providing measurable ROI for customers. Their RaaS and SaaS models further ensure adaptability and scalability, making them a long-term partner for industries undergoing digital transformation.

ANYbotics’ contributions also align with a broader global shift toward digital transformation. As industries adopt more advanced technologies to improve efficiency and sustainability, robotics plays a pivotal role in bridging the gap between the physical and digital worlds. By enabling real-time data collection, analysis, and actionable insights, robots like the ANYmal-D accelerate the transition to smarter, more connected industrial ecosystems.

TDK Ventures seeks to amplify ANYbotics’ impact by leveraging what we call “TDK Goodness” — a unique combination of in-house technical expertise, decades of experience in scaling technologies, and a global network of collaborators and customers. Our role is not just to provide capital but to actively support and accelerate innovators like ANYbotics. By connecting them with the resources, expertise, and partnerships they need to scale, we aim to maximize their potential and help them deliver transformative solutions on a global scale.

Together, TDK Ventures and ANYbotics are driving the future of industrial robotics, paving the way for safer, more efficient, and more sustainable industries worldwide.