David Delfassy and Joshua Rubnitz | TDK Ventures

Deploying Clean Hydrogen Across Industries Remains a Formidable Challenge

Though hydrogen is popularly viewed as an alternative fuel or chemical feedstock that promises lower carbon emissions than conventional technologies, it is currently a widely-used, highly polluting chemical. Hydrogen production emits around 1 gigaton of CO2 annually — around 10kg of CO2 for every kilogram of H2 produced. This carbon intensity stems from conventional production processes, namely the partial combustion of hydrocarbons such as natural gas, or worse — coal.

In recent years, a push for low carbon hydrogen has gained momentum. Rather than utilizing dirty feedstocks to produce what could otherwise be a clean molecule, hydrogen produced via the electrolysis of water offered a superior pathway, requiring only water and electricity as inputs. “Green hydrogen” went on to be well funded by climate investors and traditional venture capitalists. Despite significant funding, green hydrogen has severely lagged deployment expectations.

Yet, despite significant momentum and funding, real-world deployment remains far below expectations, as seen in recent IEA forecasts.

Of the 1.7MT of green hydrogen electrolyzers that the IEA had forecasted in 2021 to be deployed by 2024, only about 0.175MT has been deployed. This falls well short of making a dent in the hydrogen industry that consists of about 97MT of hydrogen production. While green hydrogen could make economic sense in specific geographical and industrial use cases for certain customers, in most cases it is too expensive to build and too energy intensive to run economically.

Cost, energy consumption, and plant footprint are paramount for customers

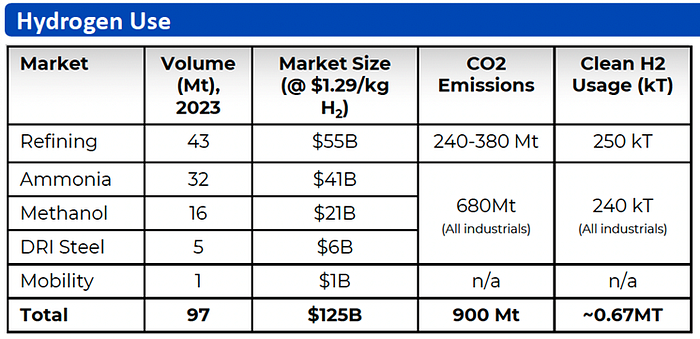

TDK Ventures sought to identify the challenges that have slowed green hydrogen rollouts. Research began with the recognition that a vast majority of hydrogen is utilized by heavy industrial customers such as ammonia production, crude oil refineries, methanol production, steel production, and other chemical refineries. Likewise, most hydrogen is produced on-site for utilization as a reactant or treatment process gas at the site of generation.

Direct discussions with a number of these large industrial customers revealed that the cost of existing green hydrogen technologies was simply too high, reaching $3–$5/kg at best and often significantly higher. Compared to steam methane reforming’s cost of $1–$2/kg, this cost point is inefficient for widespread adoption. Furthermore, large-scale projects require co-location with industrial off-takers to avoid prohibitive transportation costs, yet building new infrastructure demands significant land and capital.

As many industrial customers require tens to hundreds of tons of hydrogen produced per day, this requires hundreds of megawatts, even gigawatts, of power production capacity for green hydrogen. Splitting water into hydrogen is fundamentally energy intensive: requiring up to 50–55 kWh per kg of hydrogen. The infrastructure and land footprint to produce this much green energy via solar, wind, and batteries renders many interested customers unable to move forward with significant green hydrogen infrastructure. Furthermore, the electrolyzers themselves take up significant factory footprint and infrastructure support.

Turquoise hydrogen could meet the needs of most industrial customers

Turquoise hydrogen refers to the splitting of methane (CH4) into hydrogen and a solid carbon powder. This splitting of a molecule by thermal decomposition is known as pyrolysis, which is spurred by heating a feedstock without the conditions required for combustion — no oxygen in this case. Methane undergoes pyrolysis at approximately 1100°C in the absence of a catalyst. Thus, turquoise hydrogen is often referred to as “methane pyrolysis”. Both the hydrogen and the carbon produced in this process are viewed as valuable co-products and can be sold into individual markets.

Methane composes 95–97% of natural gas, making natural gas a suitable feedstock that is widely available globally. In the United States, for example, there are over 2.5 million miles of natural gas pipelines, whereas there are only about 1,600 miles of hydrogen pipelines. This abundance of feedstock delivery makes on-site generation and avoidance of transportation much more feasible for industrial customers. Importantly, turquoise hydrogen offers a compelling solution to key barriers that have hindered low-carbon hydrogen adoption: with energy requirements as low as 10 kWh per kilogram of hydrogen and a land footprint nearly eight times smaller than green hydrogen, it is particularly well-suited for industrial-scale deployment.

Though theorized for some time, turquoise hydrogen has yet to be mass adopted and lags the funding that has gone into green hydrogen. A major challenge for utilization of methane pyrolysis in hydrogen has been the stoichiometry of methane. Utilizing CH4 as a feedstock results in 3 kilograms of solid carbon for every kilogram of hydrogen produced. It is not only challenging to handle this much material, but the nucleation of carbon particles can cause reactor fouling, impairing the performance of turquoise hydrogen reactors.

Due to this mismatch in stoichiometry, numerous companies in this space have chosen to focus on carbon production as their flagship product, rather than hydrogen. Carbon markets include additives for industrial rubber, such as tires, graphite for battery electrode material, amorphous carbon for asphalt enhancement, and more.

Furthermore, methane pyrolysis has often been overlooked by investors due to its reliance on natural gas, which has caused it to be seen as a transitional solution rather than a permanent alternative. This perception contrasts with green hydrogen produced using zero-carbon electricity, which can achieve nearly 100 percent emissions reduction. While the pyrolysis reaction itself generates very minimal emissions, the process still carries upstream risks, such as fugitive methane emissions from pipeline leakage, and it requires continued natural gas extraction. Despite these concerns, methane pyrolysis can reduce hydrogen-related emissions by 80 to 95 percent compared to steam methane reforming, making its decarbonization potential competitive with green hydrogen. Its relatively low emissions footprint, especially when considering the scope 3 emissions often associated with green hydrogen, makes methane pyrolysis a compelling and arguably more practical solution for low-carbon hydrogen.

Turquoise hydrogen technologies

Within turquoise hydrogen, there are a number of approaches that have been attempted, with some entering early stages of commercialization:

- Thermal plasma/plasma torch: utilization of a plasma torch has been widely researched and is entering early commercialization as an effective method of methane pyrolysis. In this thermal plasma, the methane can be heated well beyond its pyrolysis point of 1100°C — commonly up to 1750–2750°C. This technology offers precise control of the reaction and plasma volume, offering consistent carbon morphology and hydrogen quality. However, technologies such as the plasma torch require orders of magnitude of scale to achieve tens to hundreds of hydrogen production per day. Industry leader Monolith Materials has had to construct “the world’s largest plasma torch” to reach early commercial scale. This massive scale up incurs stress on the system of the active components as well as the entire energy infrastructure supporting the reactor. Furthermore, given the steep temperature change between the arc plasma and the cold gas, there can be a significant variation in carbon quality.

- Cold/Non-equilibrium plasma (NTP): to eliminate risk of carbon fouling, and to keep the bulk gas temperature lower, a non-thermal plasma, such as a microwave plasma, can be used. In this plasma there is generally no direct contact between the electrode and the reactant gas, thus ensuring stable and scalable production of hydrogen. This also reduces requirements on reactor materials as the bulk gas remains at relatively low temperature, though the hottest part of the plasma can reach up to 3750°C in some cases. While NTP offers a lower temperature alternative to thermal pyrolysis, the energy consumption for hydrogen production via NTP methane pyrolysis can still be relatively high compared to steam reforming. Furthermore, the conversion of the reaction and the quality of carbon can vary widely across the plasma volume, creating complex byproducts and there are still challenges in scale up and hence commercialization due to Microwave penetration limitations.

- Catalytic pyrolysis: catalyst-based pyrolysis can lower the temperature of pyrolysis conversion, allowing for thermally based pyrolysis at low temperatures. A number of catalysts have been proposed including molten metals, molten salt, and solid catalysts (such as iron oxide). In the case of both molten materials, they benefit from relatively high catalyst stability, but struggle with yields and carbon quality due to the direct contact between the molten material and the carbon, hindering clean separation of the two materials. Solid carbon can struggle with poisoning of the catalyst as solid carbon nucleates on the surface of the catalyst.

Why we invested in Tulum

Twenty years before Tulum Energy raised its seed round, engineers at Tenova, a world leader in steelmaking equipment, discovered an unexpected trend: while they were performing an experiment in a steel producing furnace by passing methane through hollow carbon electrode, the electrodes themselves, were growing larger during experimentation, rather than wearing out. The engineers at Tenova had discovered that their “electric arc furnace” was inducing hydrogen plasma and solid carbon nanotubes from pyrolyzing methane. Decades later, this technology was rediscovered by TechEnergy Ventures, the venture arm of Tenova’s parent company, Techint Group.

Tenova is a leading provider of metallurgical equipment, known for delivering manufacturing solutions such as electric arc furnaces used in steelmaking. An electric arc furnace can form electric arcs capable of melting iron or scrap steel for refinement into an end product, typically steel. These massive instruments can reach temperatures of over 3000°C and deliver electric power of over 200MW. Importantly, this technology has been used commercially for over 100 years. It is mature and well understood.

By leveraging this technology as a building block for their reactor design, Tulum can accelerate technology deployment and significantly mitigate scale up risks of their system in terms of the logistical overheads of power delivery and component selection. This allows for striking of a thermal plasma that brings the bulk temperature of the methane feedstock well beyond the temperature required for pyrolysis, ensuring complete and consistent conversion to hydrogen and solid carbon at very large scale. In short, Tulum can leverage the benefits of a thermal plasma system without risking the large scale up required by other designs.

Tulum’s relationship with Tenova, and utilization of a well-known reactor vessel brings much more value in addition to the schematic design of their reactor. Tenova delivers fundamental know-how for simulation work in this mature product. This has led to high confidence in process simulation of the methane pyrolysis process and leading to well-known fluid dynamics and reactor design guidance. Furthermore, Tenova has provided valuable consultation on the implementation of refractory materials and a custom-built heat exchanger to optimize energy use.

Tulum’s equilibrium plasma utilizing this mature technology enables metrics that TDK Ventures believes is required for wide adoption of turquoise hydrogen including:

- Cost Competitiveness: Even at early scale, Tulum’s pilot objectives target a production cost of $1–$2/kg without the sales of carbon co-products or accounting for any subsidies, matching steam methane reforming, through low-energy requirements and reasonable capital expenditure. For ease of integration, their process leverages existing natural gas infrastructure. Therefore, Tulum expects to sell hydrogen at this competitive price point.

- Scalability: By leveraging electric arc furnace design principles, Tulum’s reactor can deliver over 100MW of power to produce over 200 tons of hydrogen per day. Tulum intends to create a system that can deliver the amount of hydrogen that industrial customers need: tens to hundreds of tons of hydrogen per day.

- Small Footprint: By co-locating with industrial facilities for point of use hydrogen and carbon production, Tulum minimizes land and transportation costs, addressing infrastructure challenges. Tulum’s energy efficient process requires much lower land overheads when compared to other forms of low carbon hydrogen.

- Carbon Co-Product Value: Though Tulum’s hydrogen price is competitive with SMRs even without carbon sales, Tulum’s process is expected to yield high-quality carbon products with growing markets projected to add significant revenue streams.

- Environmental Impact: By avoiding the combustion of hydrocarbons, Tulum eliminates nearly all direct (Scope 1) emissions. As a result, the carbon intensity of its hydrogen production can be reduced by up to 95 percent compared to conventional methods — comparable with the reductions achieved by green hydrogen solutions.

Given the attractive attributes of Tulum’s methane pyrolysis reactor and the proceeds from its oversubscribed seed round, Tulum will soon begin construction of its inaugural pilot plant in Pesquería, Mexico. The plant will be co-located within the industrial complex of Ternium, Latin America’s leading steel producer and part of the Techint Group. This site hosts a DRI steel plant capable of producing low-carbon steel and has the potential to use hydrogen as a feedstock.

Finally, Tulum is led by industry veterans with a unique blend of experience in early-stage venture building and the green chemicals sector. CEO, Max Pieri, previously led M2X Energy as the CEO. M2X is developing solutions to produce low carbon chemicals, specifically methanol from waste methane. Prior to that, Max had spent 15 years at Eni, where he ultimately established Eni Next, Eni’s corporate venture capital arm. Prior to joining Eni, Max was part of the GE Capital M&A team in London. Heading the technology is CTO Dr. Donald Kendrick, who brings over 30 years of experience in power generation, renewable energy, and clean technology innovation. He spent much of his career at United/Raytheon Technologies, including serving as Operations Manager at Pratt & Whitney’s PulseDyne division. He has also held leadership roles at several clean tech startups focused on commercializing disruptive technologies. Most recently, he was the CTO of Ekona, a methane pyrolysis company developing a novel pulsed thermal pyrolysis platform.

TDK Ventures is Proud to Partner with Tulum as They Pioneer Industrial Scale Low Carbon Hydrogen

TDK Ventures strives to invest according to our triple bottom line: outsized financial returns, strategic value to TDK, and contribution to society. By delivering a scalable solution to decarbonize the $125B hydrogen industry Tulum can bring one of the first scalable solutions for low carbon hydrogen to eager customers. Tulum’s technology aligns with TDK’s expertise in power supplies, high-power capacitors, and high-frequency transformers, offering potential synergies for component integration. Learnings from Tulum’s carbon morphology could inform TDK’s battery material applications, enhancing our portfolio of energy transformation products. All while significantly reducing the emissions from this sector that can emit nearly 1GT of carbon dioxide annually.

TDK Ventures’ investment in Tulum’s Seed round reflects our belief in their potential to lead the low-carbon hydrogen transformation. Tulum’s methane pyrolysis technology addresses the critical challenges of cost, scale, and infrastructure, delivering a sustainable solution that matches steam methane reforming economics while matching green hydrogen’s environmental performance.